The main component of the modular system is the smart GLD 202, or GLD 204, Leak Detector which stores multi-sensor signals from the pipeline and, following internal processing, prepares them for later analysis.

Liquid pipelines from 8” in diameter

The main component of the modular system is the smart GLD 202, or GLD 204, Leak Detector which stores multi-sensor signals from the pipeline and, following internal processing, prepares them for later analysis.

Liquid pipelines from 4” in diameter

Chassis for the GLD 202 / GLD 204 that is specially designed for the corresponding pipeline. It supports the leak detector and centres it inside the pipeline. It is propelled by the pumped medium and has an additional distance and velocity measurement system.

Features

Liquid pipelines from 4” in diameter

ATEX 0 certified

Charger unit and interface between the GLD 202 and the GLD 710. It is used for charging the batteries, data transfer, and system monitoring.

Charger unit and interface between the GLD 20x and the GLD 710. It is used for charging the batteries, data transfer, and system monitoring.

The US marker produces an induced, defined 35 kHz signal inside the pipeline, and serves as a way point marker for smart pipeline pigs.

Features

Gas and liquid pipelines

ATEX 1 certified

The electronic, artificial leak transmits a signal inside the pipeline which simulates a real leak, and serves as verification of the leak detection system.

Features

Gas and liquid pipelines

ATEX 1 certified

Magnetic pig signaller for pig tracking, as well as pipeline operational management.

GLD 611 features – General

GLD 611 features – Central Unit

GLD 611 features – Sensor

Gas and liquid pipelines

ATEX 1 certified

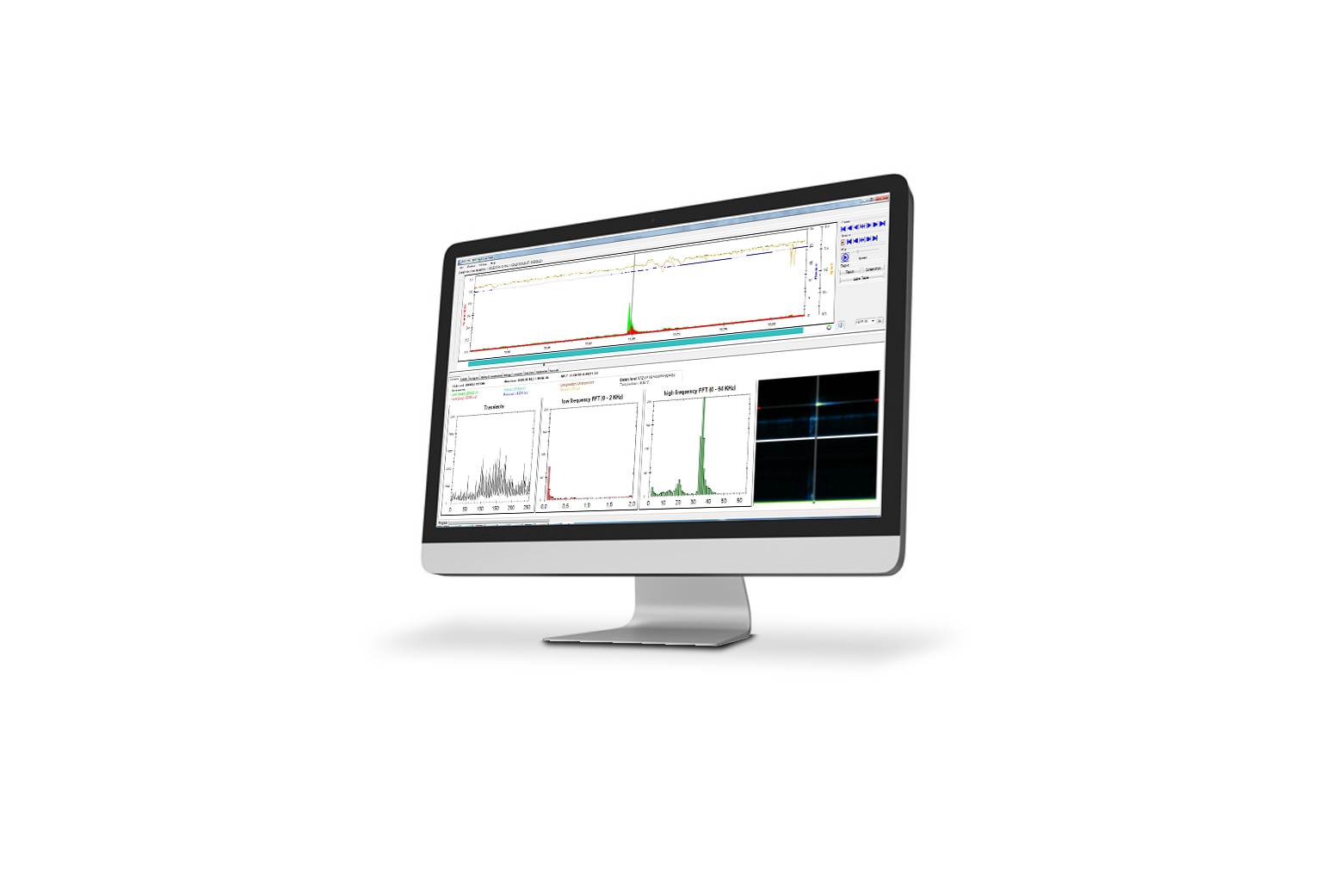

Analysis software for evaluating GLD 20x run data.

Features

Fully-automated fixed artificial leak for generating a real-world monitored leak.

Features

Gas and liquid pipelines

Flexible separator balls for separating, or loading different product qualities.

Gas and liquid pipelines

ATEX 0 certified